|

|

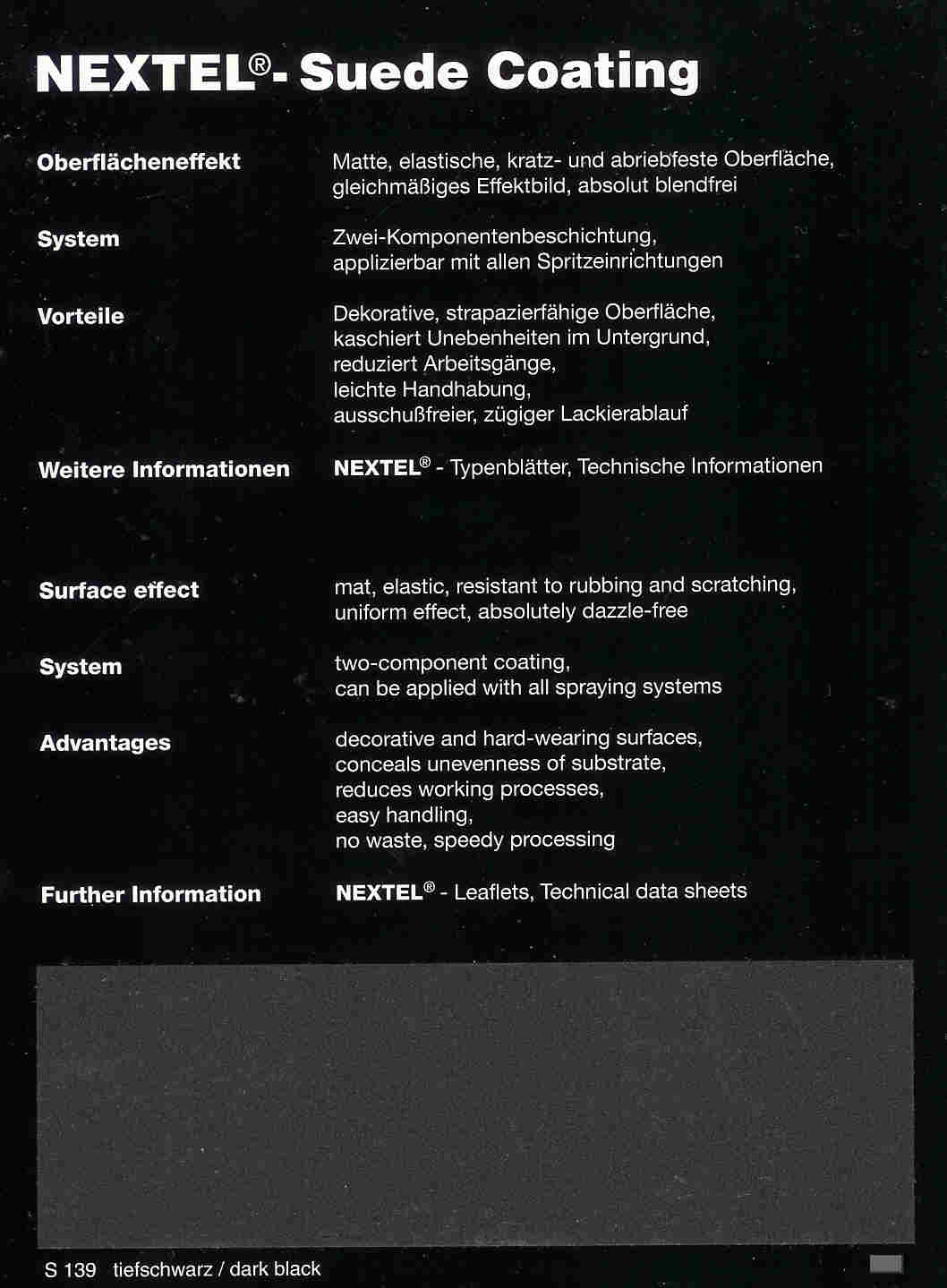

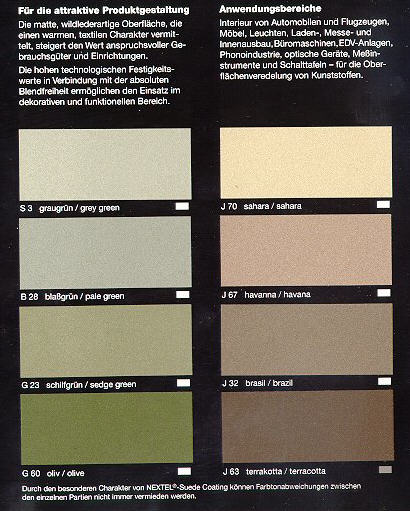

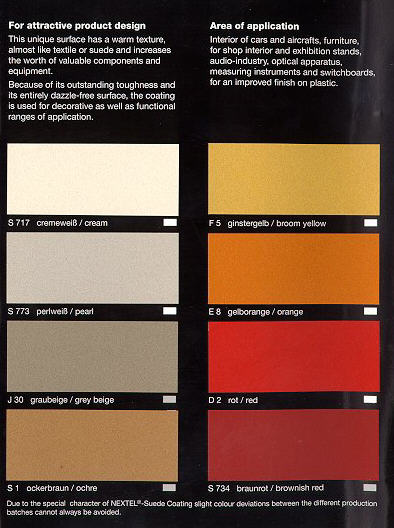

EC console & Prodesk standard NEXTEL colour finishes: EC-CONSOLES: colour B21 dark anthracite PRODESK CLASSIC: colour B21 dark anthracite PRODESK

Free-form: All these colours are stock colours and can be used for a few desks or consoles without any extra costs or delay. Pe. You can do a few consoles completely in dark anthracite but with the deskpanels in colalt blue, as you can see on some of the photagraphs in the photo galleries. |

Nextel Colour Finishes

'NEXTEL' was originally developed by 3M Company in the USA following a request from NASA for a special coating for use on the interior surfaces in the Space Shuttle.

The criteria were that this coating had to:

1. Have excellent Anti-static properties.

2. Be chemically inert.

3. Absorb scattered light and be totally non-reflective.

4. Be very hard wearing and scratch resistant.

5. Be resistant to stains and easy to clean.

6. Be warm to the touch.ELDECO & MW Video have chosen to use NEXTEL Colour finishes on a number of their technical furniture products. NEXTEL provides an unusual and attractive high quality finish which is also extremely hardwearing and has been particularly chosen by MW because of its special qualities. Like any surface however, it need to be treated in accordance with the manufacturer's recommendations in order to get the best results and to maximise its durability. The enclosed information should be referred to when installing NEXTEL finished products and the recommended procedures for maintenance and repair followed.

NEXTEL 3101 Coating is a unique surface finish.

Nextel Colour Finishes technical & practical information

MW

& ELDECO cannot be held responsible for damage occurring to NEXTEL

finished products that have not been treated in accordance with the manufacturers

recommendations.

GENERAL INFORMATION

NEXTEL 3101 Coating is a unique surface finish.

Composed of microscopic neoprene granules in a special carrier medium,

the finished coating has a soft warm texture, almost like a fabric. The

composition of NEXTEL 3101 gives an entirely glare free finish, a matt

quality that lasts throughout a long working life. The colour range is

almost infinite; careful blending of primary colours ensures matching

of any tone or shade.

Once applied, NEXTEL 3101 has outstanding scratch, knock and abrasion

resistance, shakes off virtually all household and office stains and is

not affected by either wet or dry heat. When cleaning becomes necessary,

NEXTEL Coating can be scrubbed with detergent, methylated spirit or washing-up

liquid without damage. The colours, in all normal circumstances are fade-free.

Should the surface ever need repairing, this can be easily accomplished

by re-touching; the repair will be a precise match to the original.

NEXTEL 3101 Coating has been successfully applied to a wide range of substrates,

including wood, metal, plastics, card, paper, fabrics, glass and asbestos.

Application is extremely simple; all that is required on most surfaces

is ONE coat of NEXTEL 5523/4 primer, and ONE coat of NEXTEL 3101 colour.

Further coats are not required. On particularly porous surfaces, such

as softwood, an initial coat of a suitable primer/filler is recommended.

Standard industrial spraying equipment gives a perfect result, either

in the workshop or on-site. Pre-treatment of the substrate is kept to

a minimum; cleaning and de-greasing for metals, sanding for grained woods

and removal of release agents on plastics. For optimum results, the coating

can be dried by stoving at temperatures up to 15°C; excellent results

can, however, be gained by air-drying at any temperature over 17°C.

The applications for NEXTEL 3101 are almost unlimited. The choice of substrates

available make NEXTEL Coating particularly suitable for the interior designer:

furniture, fittings and equipment can be co-ordinated to produce an integral

result.

The combination of on-site and workshop applications offers great flexibility

in construction. For the product designer, NEXTEL 3101 gives a long-lasting,

hard-wearing finish ideal for furniture, office and domestic equipment,

T.V., radios, hi-fi, etc., in fact, all high quality products can

benefit from NEXTEL Coating. It is especially attractive when high-lighted

by combination with other materials; high-gloss or brushed metal finishes,

rich wood grains, contrasting gloss paints. The design possibilities are

endless.

CLEANING

A. Dust and finger marks can be removed by means of a soft brush, moist

cloth or sponge. Removal is facilitated by using aqueous detergents, washing-up

liquid or methylated spirit.

B. Stains caused by mineral oils, lubricants, vegetable fats, can be removed

with a cloth, sponge or brush together with methylated spirit or isopropyl

alcohol.

C. Stains caused by water-soluble agents such as jam,tea,coffee,

fruit juice etc. can be removed with a cloth, sponge or brush together

with aqueous detergents, washing-up liquid, or a light scrubbing with

a moist SCOTCHBRITE pad.

In all cases, a regular cleaning schedule will prevent the build-up of

stains, which may, in time, prove difficult to remove.

REPAIR

It is very difficult, but not impossible to damage a correctly applied

NEXTEL Coating. Should damage occur, there are two possible techniques:

1. SMALL AREAS:

Small areas of damage should be lightly stippled with Primer 552314 and

then again with top-coat. It is advisable to widen the area covered, in

order to better blend in with the original coating. Note that ELDECO has

small NEXTEL repair units available for the standard stock colours like

colour B21 dark anthracite, S757

cobalt blue, 734 brownish red and S139

dark black

2. LARGE AREAS:

Repairing large areas of damage or a complete re-coating in the same or

another colour can be achieved by re-spraying with Primer and topcoat.

Spray the surface with Primer 5523/4 with a very dry film of 10 microns

(0.0004 in.) thickness. If the surface is being re-sprayed with a light

or bright coating of NEXTEL 3101, the primer coat must be sprayed thinly

but nevertheless must cover the original coat.

After re-spraying with top-coat, the overall coating is now considerably

thicker and should be dried at an increased temperature of 60°-80°C.

On air-drying, parts should be handleable after 24 hours. The surface

will, however, retain solvent and will take several days to become hard

dry.

REMOVAL

NEXTEL Coating can generally be removed from metallic substrates by conventional

paint removers (methylenechioride type) and ketone solvents, e.g. M.E.K.

On old surfaces, the action may be slow. On plastic surfaces, check the

solvent effect on the plastic.

Rapid removal may be accomplished by phenol-type removers, subject to

the necessary safety precautions recommended by manufacturers.

PLEASE NOTE: Comprehensive Data Sheets Available on Request

For buying Nextel coating: Please contact the manufacturer on website https://www.mankiewicz.com/en/company/locations